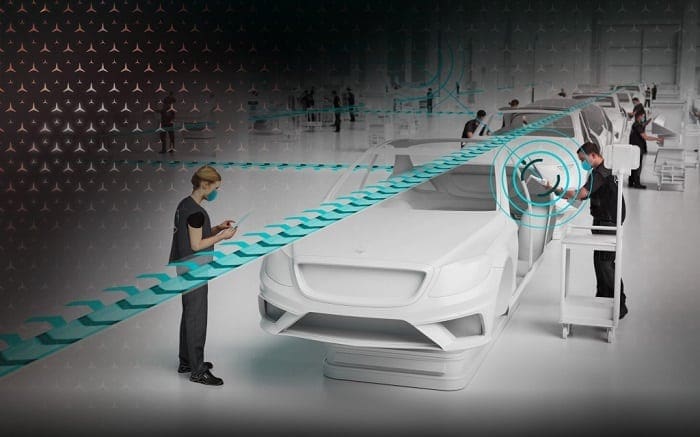

Mercedes-Benz and Siemens plan to cooperate on advancing digitalization and automation in the automotive industry. The carmaker aims to digitize its production processes.

Siemens, a leading supplier in the field of automation, industrial software and smart infrastructure, will bring its expertise and technologies to the partnership to develop highly flexible, efficient and sustainable automotive production together with Mercedes-Benz.

“Mercedes-Benz takes digitalization to the next level in the global Mercedes-Benz Cars production network,” Jörg Burzer, Member of the Board of Management of Mercedes-Benz AG, Production and Supply Chain Management, said.

“Together with Siemens, we are driving forward the development of sustainable future technologies – from Berlin for the whole world.”

In this context, the Mercedes-Benz Berlin-Marienfelde site in Germany will be transformed into a competence centre for digitalization with a focus on the development and implementation of the digital Mercedes-Benz Cars ecosystem MO360 (http://mb4.me/UWbRz2GR), in addition to the redesign of production activities.

“We are further expanding our decades-long successful cooperation with Mercedes-Benz in the field of engineering and production. Together, we want to take the next big step towards sustainable and even more competitive automotive production.” Cedrik Neike, Member of the Managing Board of Siemens AG and CEO Digital Industries.

“To achieve this, both partners rely on end-to-end digital technologies to connect technology, sustainability and new working environments more closely than ever before.”

Siemens leading automation and software solutions lay the foundation for the digital transformation of automotive production. The physical and virtual worlds as well as operational technology and IT can be combined with them.

The company’s said this opens up new possibilities for gathering, understanding and using the huge amounts of data generated in engineering and production. “With innovative IoT applications, for example, production processes can be made much more flexible and energy-efficient.”